About The Invention

The SandWorkz ASMS

The SandWorkz Automated Sand Management System is a device to be used during the process of the fluid removal from the wellbore. It allows for remote login monitoring into the system and provides the ability to view sand production numbers made from the day the well opens through the current date. This will allow the parties responsible for the well to see the numbers first hand. As well as having an accurate method to real sand production.

This system does not remove the sand from the fluids being removed from the wellbore, but it does however monitor and report actual sand production from the wellbore.

Why is accurate monitoring of the sand important? Simply put, the less sand being sent to the operating companies production facility means, less shut down and repairs due to sand erosion and washout of equipment, iron, etc.

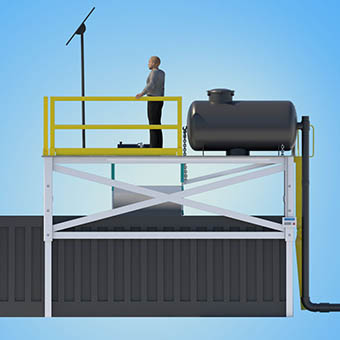

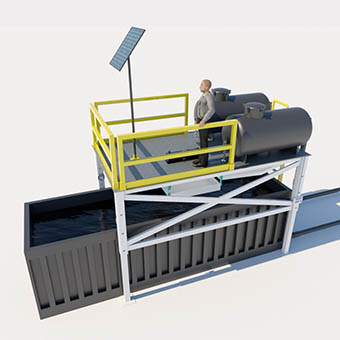

The Automated Sand Management System consists of metal platform that is shipped to the location and then extended to fit over fluid collection tanks.

It consists of:

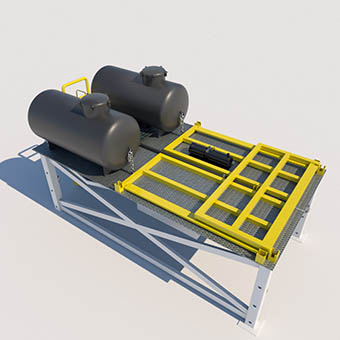

A steel platform with extendible steel legs

Two “gas buster” tanks for stabilizing the fluids by relieving gas pressure

Certified safety railing and foldable ladder which break down for storage and moving

Adjustable chain suspended ramp for directing fluid and sand from “gas buster” tanks above

Hydraulic controlled capture box for collection and weighing of fluid and sand

Hydraulic controller and manifold

LCD control panel for controlling and monitoring the equipment

Solar panel for onsite power

Simplified description of process

As the fluids come from the wellbore, they go through several pieces of equipment with different functions. One function is to remove the sand from the fluids being removed from the wellbore using sand traps. Once these are dumped as needed the contents are sent to the ASMS. Once the fluids pass through this “gas buster” the fluids fall through the bottom of the tank with the sand that comes with it.

Once it falls through the tanks it hits a slide and comes to rest in a two-part capture box underneath. This capture box is supported by eight hydraulic cylinders. The four corner cylinders are attached to an electronic scale, which sends the accurate weight data to the control panel and also to remote monitoring locations. Once weighed, the capture box is opened with the hydraulic cylinders to let the fluid and sand fall into the tank below. The capture box then returns to the up position ready for the next round of fluid and sand.

The system is made to easily break down to half of its size for efficient shipping to a new location.

Product Images

About the Inventors

Michael Metcalf

Charles Worthy, Jr.

About the Developers

MetWorthLLC was formed in November 2018 by two individuals who foresee bigger and better opportunity in the oil and gas industry. This company is aimed at setting an industry wide impact on the production and well testing phases of the past present and future wells drilled across the United States.

Having over 10 years of experience in the oil and gas industry, They came up with and idea to monitor sand production accurately to help reduce short and long-term cost of shutdowns and repairs of production facilities and equipment due to sand erosion. Having the hands-on experience of the equipment and the problems that occur at these facilities, the idea of the Automated Sand Management System was born.

The invention has been thoroughly designed so that they may see success with this great idea and turn it into a world-wide product. They are actively seeking a company that would have an interest in licensing the system for a royalty.

Contact The Inventors

PH: (903) 631-1014 Michael

PH: (903) 932-8436 Charles

Website: www.MetWorthLLC.com

Contact By Email